Pushkar Kumar grew up in India, where, he says, plastic trash piled up everywhere. He understood the waste was actually a vast storehouse of energy and, with his father, a renowned chemical engineer, decided to learn how to recover it.

Their work began in a small garage. Now, with the younger Kumar in Canada, it has become GreenMantra Technologies, an ambitious startup aiming to solve one of the toughest problems of Ontario’s Blue Box recycling program – finding an economic use for plastic bags and film.

GreenMantra is among a handful of companies to benefit from a new strategy employed by Stewardship Ontario, the private, non-profit agency created 11 years ago by the provincial government to operate the Blue Box program.

The program, the world’s first when introduced in 1981, collects paper as well as metal, glass and plastic packaging from nearly five million households. It generally costs far more to operate than it earns from selling the recyclable materials for which there is a market. The shortfall is shared about 50:50 between municipal governments and the manufacturers, importers and retailers, known collectively as “stewards,” whose products generate Blue Box materials.

Under the 2002 Waste Diversion Act, stewards pay fees, which Stewardship Ontario then uses to help create a marketplace for recyclers. The program has achieved a 65 per cent rate of diversion from landfill, exceeding the target of 60 per cent, says the agency’s executive vice-president, Lyle Clarke. But he says staying above the target is a challenge as readily recyclable newsprint continues to decline and packaging becomes more complex and difficult to process.

Thus, the organization began investing in innovative solutions. “We have a mandate and obligation to expand the marketing of Blue Box materials,” Clarke says.

The new packaging is not necessarily bad news for the environment, he adds. It can cut a product’s carbon footprint by reducing weight or, in the case of fresh foods, spoilage. “We’re trying to make sure the Blue Box system can adjust and adapt … to reduce the overall carbon footprint of the product stream.”

Stewardship Ontario’s initial move in this new direction came in 2006, when it solicited expressions of interest from companies with ideas on how to handle the tougher Blue Box materials. In 2008, it imposed an additional $2.4 million in stewards’ fees to fund the expansion. Two were chosen.

Entropex is an improved system for sorting all post-consumer plastics, allowing more material to be pelletized into a new feedstock for manufacturers. EFS-plastics produces pellets from rigid containers, bags and film. When those businesses, which received other publicand private financing, did well, “our thinking evolved about how we could advance the strategy,” Clarke says. “We looked at a number of sources for inspiration.” One was the MaRS Discovery District in Toronto, a public-private partnership that acts as an incubator, turning scientific innovation into commercial products.

“We asked: How could we be an incubator of innovation … creating conditions under which new companies could bring products (from Blue Box materials) to market,” Clarke says. That led to further support for EFS with $1.5 million in convertible loans to relocate and expand its plant and invest in new technology.

In a somewhat unique move for an organization of its type, Stewardship Ontario then made its first investment in an early- stage project. It put $500,000 in equity into Switchable Solutions, developing a “green solvent” process to let polystyrene – used for take-out food containers, plastic cutlery, foam carton liners – be recycled, with low energy consumption.

The company planned a factory in the Toronto suburb of Mississauga to process two million tonnes of material annually. But its technology was also useful in oil sands extraction and it shifted to the energy industry. “That happens in early-stage commercialization,” Clarke says. “Market opportunities can drive it in a different direction. That’s part of the excitement.

“Eventually it will help us. Technological solutions will be useful looping back to plastic packaging.”

Kumar was on the hunt for private investments when, in 2011, he met Clarke at a conference. That encounter led to Stewardship Ontario’s only other early-stage investment to date, a $1.5 million convertible loan approved in May 2012. “They were a key part of the puzzle,” says Kumar, who also got support through MaRS and private sources. “The money from them was very important to build our production line.”

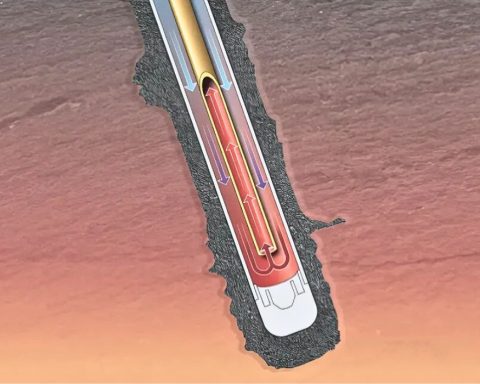

The process seems simple. Heat the plastics in an oxygen-free environment and add a catalyst. The result is a range of products – wax, grease, lubricating oils or fu- els – that can replace those mainly made from petroleum. The key, and secret, ingredient is the catalyst. It took years to develop one that works effectively at a

reasonable cost and that can be reused many times. “If I told you what was in it, I’d have to shoot you,” Kumar says with a laugh.

GreenMantra now focuses on making waxes, used in asphalt, shingles, paint, particleboard, toilet seals and many other products. These are currently its most prof- itable products, requiring less heating and fetching higher prices than the others.

The company’s Brantford, Ontario, factory processes up to 3,000 tonnes of plastics annually – a sliver of both the province’s 100,000 tonnes of plastic waste and the $10 billion world market – “but we’re expanding.” The existing plant has room to process up to 12,000 tonnes, and the company might eventually expand into the much larger grease, oil and fuel markets, Kumar says. Clarke won’t discuss potential further investments except to say Stewardship Ontario is always looking for opportunities. “Our door is always open,” he says.