It all started in 1923 when a young Japanese man saw that the world around him was changing. It was getting brighter – literally. Once a community of sea merchants, the town Osaka he knew so well was transforming into a bustling manufacturing centre as a result of the electrification of everything from street signs to transportation.

As he observed these shifts, the young man saw the potential to improve people’s lives by making technology more energy-efficient.

Amidst growing electrification, the country’s bike riders traded their flame lamps for battery-powered electronic ones. These devices were seen as unreliable due to their limited life of only two to three hours. Over six months of testing, Panasonic founder Kōnosuke Matsushita developed a bullet-shaped bicycle lamp that could operate for 30 to 40 hours.

More than 100 years later, Panasonic’s work is still founded on these ideas: making people’s lives better by making technology more responsive and more efficient.

The one thing that has changed is our more comprehensive understanding of the impacts of industrialization on people and the planet. “The society in which we live means that the pace of consumption is accelerating,” says Markus Reichling, general manager of green transformation at Panasonic. “[It’s] a model that is fast but unsustainable for the planet.”

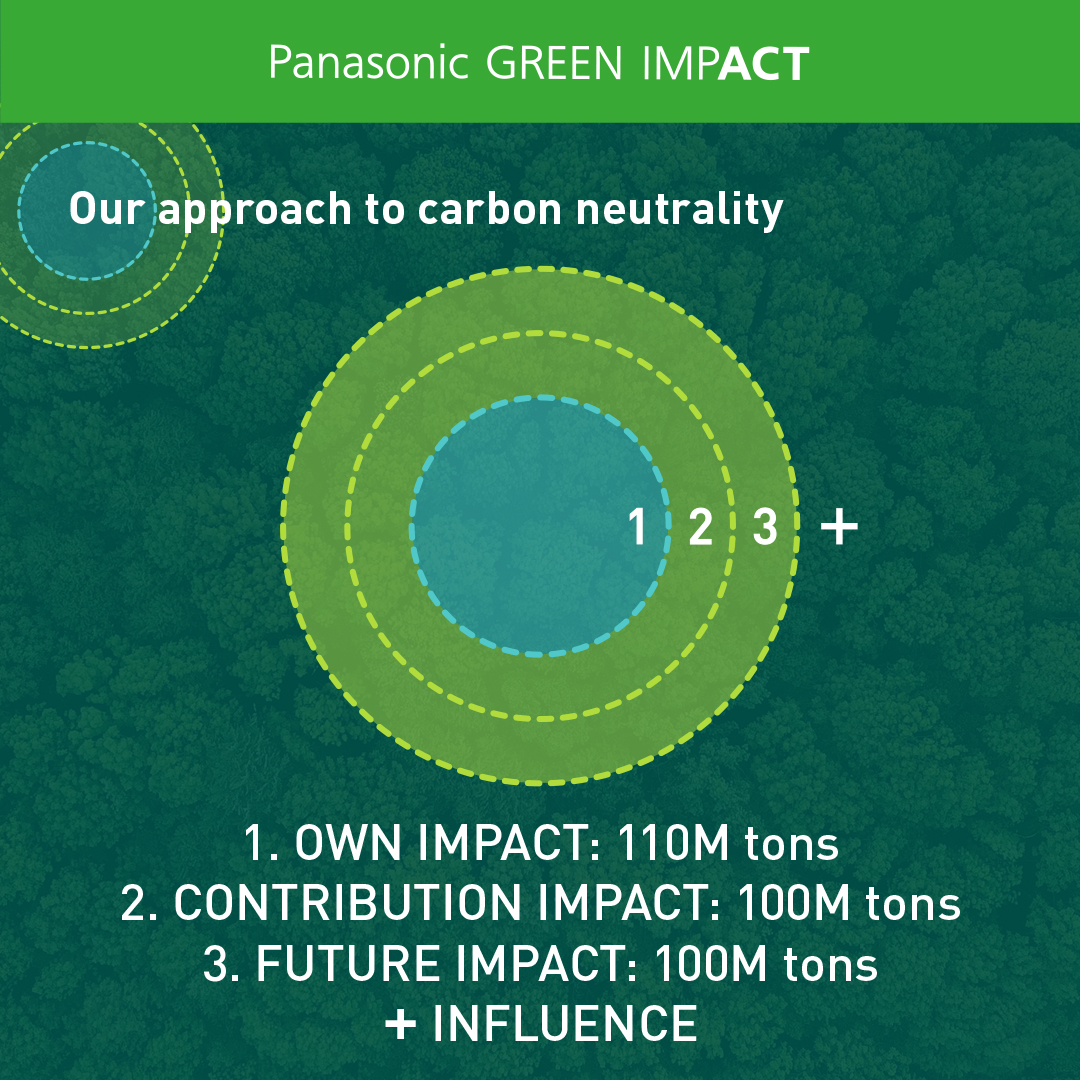

To help address climate change with the urgency it requires and continue its work supporting Matsushita’s founding principles, the company publicly shared about its Panasonic Green Impact initiative for the first time in 2022 to deepen its commitment to sustainability. The company has begun the work to either neutralize or otherwise avoid more than 300 million tons of carbon dioxide as part of the work embodied by the three pillars of Panasonic Green Impact. That’s a global total of around 31.7 billion tons, according to the company’s Sustainability Databook.

Investing in the circular economy

As part of this effort, Panasonic has increased its investment in the circular economy, a system focused on reusing and regenerating materials and products to enhance production and manufacturing efficiency. “By embracing the circular economy, a product is given an extended – or even second – life and waste is reduced,” Reichling says.

One example showcasing how design can be developed with the circular economy in mind is Panasonic’s MultiShape, a personal-care product that offers multiple options for attachment heads, like a razor, toothbrush and trimmer, that are all compatible with the same base, motor and battery – and thus replacing the need for multiple individual products. The unique design could save as much as 60% of the resources it would take to make a single-function item, such as an electric toothbrush.

“Panasonic is still continuing to produce and sell individual products,” Reichling says. “But, with the MultiShape, we would like to offer the customer a more sustainable, more responsible solution.”

Cutting costs – and emissions – for its business partners

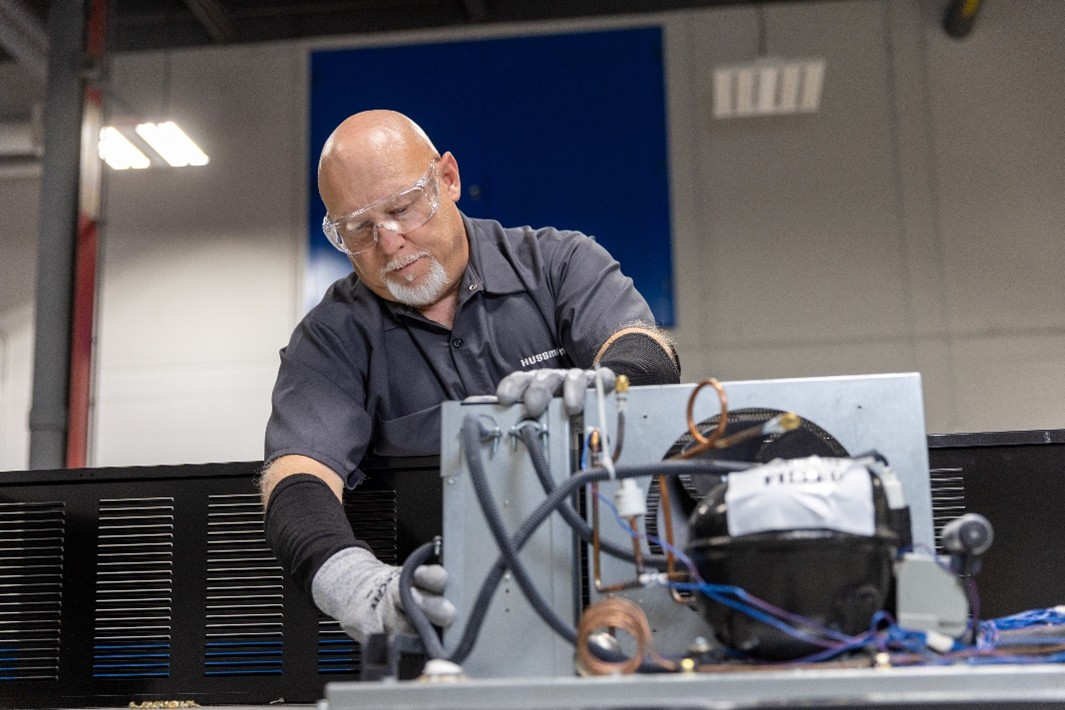

This same innovative approach applies to Panasonic’s work with its business partners: across the industries the company serves, Panasonic supplies cutting-edge solutions that prioritize longevity, resource efficiency and responsible design. Panasonic is working to advance these efforts at Hussmann, a Panasonic company – an industry leader that provides display merchandisers, refrigeration systems, connected solutions, installation and services to food retailers around the world.

Refrigeration plays a central role in the food retail industry: customers not only expect fresh quality, but spoiled food and waste increases costs for businesses. Traditional refrigeration solutions provide additional environmental challenges, chief among them continuous refrigerant leaks.

According to the Environmental Protection Agency, the average supermarket leaks almost 400 kilograms of R-404A refrigerant per year – the equivalent of emissions from 339 cars. Hussmann addressed this challenge head-on with its cloud-based platform StoreConnect that leverages advanced data analytics to detect leaks in very early stages, which traditional monitoring equipment would not detect until the system runs out of refrigerant.

Recognizing the urgency of this issue, Hussmann implemented StoreConnect in 2022 across numerous customer sites. The platform’s “advanced refrigerant leak detection” technology provides near real-time data, allowing technicians to proactively address leaks before they become critical and reduce environmental impact.

“By significantly reducing leaks – achieving 30%-plus leak-rate reductions in the first year – we’re accelerating detection, transforming refrigerant management from reactive to proactive, and ultimately minimizing environmental impact. This shift isn’t just improving operational efficiency; it’s driving sustainability and cost savings for our customers,” says Sarah Greenwood, senior vice president of connected solutions at Hussmann.

Starting at the source

Beyond the design of its products and solutions, Panasonic is working to transform its “own impact” by assessing the ways it can reduce its carbon emissions across its value chain. This starts with the company’s efforts to achieve net-zero carbon dioxide across all its manufacturing sites by 2030.

By the end of 2024, Panasonic had achieved 44 net-zero factories.

“Here in North America, Panasonic is approaching the climate crisis from a few different angles, starting with reducing our Scope 1 and 2 emissions at our Panasonic factories,” says Andrea Murphy, director of environmental affairs compliance and sustainability at Panasonic Corporation of North America.

Scope 1 emissions are emissions that occur directly in a company’s own value chain, while Scope 2 emissions are indirect emissions from purchased or acquired electricity, steam, heat or cooling that are generated off-site and consumed by the company.

To achieve these net-zero goals, Panasonic is leveraging a combination of on-site renewable energy generation – such as solar panels and hydrogen fuel cells – alongside energy storage systems to ensure a stable power supply. The company also enhances energy efficiency through advanced management systems and optimized manufacturing processes.

Working to further close the gap, Panasonic purchases renewable energy and credits. Also, the company collaborates with clean energy networks such as the Clean Energy Buyers Association – all as part of its commitment to transforming its global manufacturing sites into zero-carbon factories by 2030. “Our commitment is to reduce carbon emissions by more than 300 million tons, which we calculated to be 1% of the current global emissions,” Murphy says. “I believe that’s well respected by our customers.”

The company believes that Panasonic Green Impact is a comprehensive initiative that can have a greater influence on the larger business community by establishing these practices as a foundational part of doing business.

According to Murphy, Panasonic takes every opportunity to promote decarbonization and energy-saving behaviours among customers, businesses, governments and investors: “Our partners and suppliers are hand-chosen. We partner with companies that have very similar initiatives to Panasonic, so they’re very happy to collaborate and work together [with us] toward those common goals.”

* Panasonic Corp has ranked in the 2025 Clean200.

Andrea Murphy, director of environmental affairs and sustainability,

Panasonic Corporation of North America

Andrea Murphy is the director of environmental affairs and sustainability at Panasonic Corporation of North America. Since 2019, she has led and implemented the company’s regulatory compliance, recycling and sustainability initiatives. A key member of the company’s Global Environmental Task Force, she proudly supports Panasonic’s Green Impact initiative, dedicated to reducing carbon dioxide and promoting renewable-energy efforts that will help secure a sustainable future for customers and communities around the world.

An experienced environmental professional, Murphy has 19 years of environmental management experience, including five years focused on general management experience in project management, finance and strategy. Prior to joining Panasonic, Murphy held multiple environmental compliance roles with Verizon to focused on wireless network infrastructure, new product launches and agency relations. She also served as a regulator with the Santa Barbara County Fire Department’s hazardous materials unit, enforcing hazardous waste and hazardous materials regulatory management programs.

Murphy holds an undergraduate degree in environmental studies from the University of North Carolina at Wilmington and a master’s degree in environmental management from the University of California, Santa Barbara. She also earned her certification in Igniting Performance with Purpose from Duke Corporate Education.

Outside of her work responsibilities, Murphy serves as president of MRM E-Cycling Management, a consortium of manufacturers that aims to realize convenient environmentally responsible recycling opportunities to consumers nationwide. She is also an active member of her town’s Environmental Commission, providing leadership and vision on conservation and sustainability actions and policies for residents, businesses and natural resources. Currently, she is the executive sponsor for Panasonic’s LGBTQ+ business impact group, PRISM, supporting allyship and fostering inclusivity for all.

Recent speaking ops:

CES 2025: Rechargeable Batteries in Consumer Tech- A Path to Sustainability?

CES 2025: Circular Economy Innovations 2025