Every year in Canada, 30 million tonnes of wheat straw left over from harvesting gets left on farmers’ fields. What if you could turn some of that waste into paper products and alleviate the pressure on forests in the process?

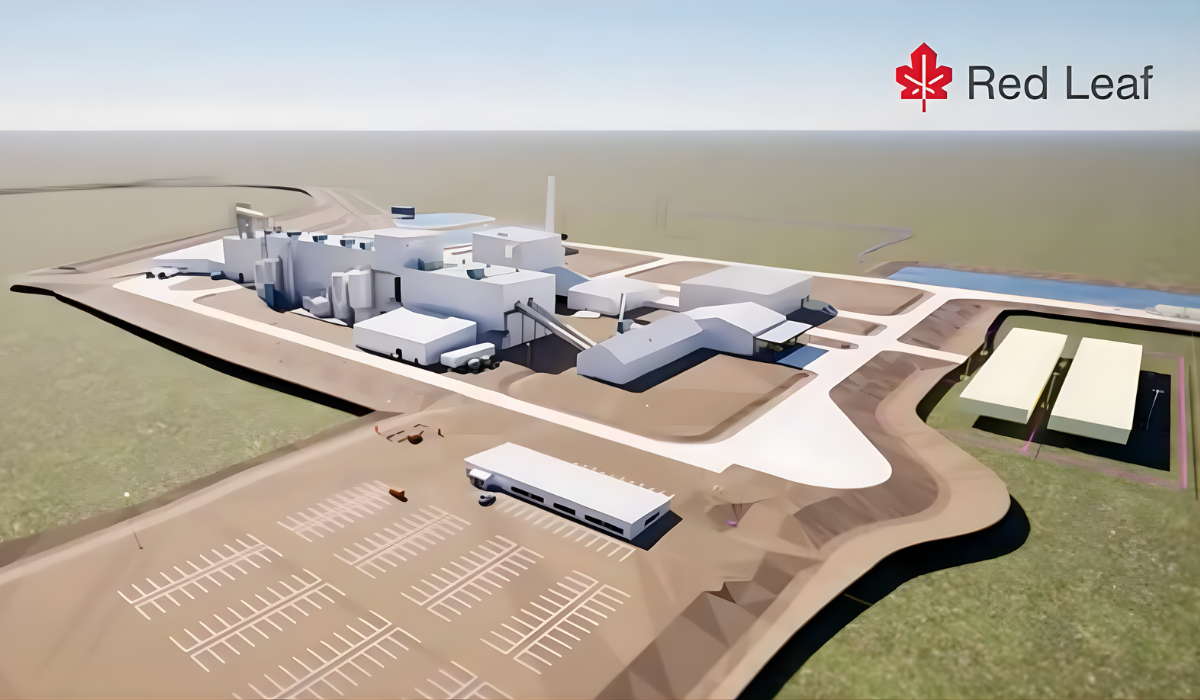

The founders of Red Leaf Pulp say they’ve figured out how to make high-quality pulp from agricultural by-products rather than wood from trees, and they’re ready to start producing at scale. The company’s first-of-a-kind pulp mill, slated to begin construction in Regina, Saskatchewan, in the first quarter of 2026, will manufacture what it calls “climate-positive, non-wood pulp” using a process that consumes 95% less water and 70% less energy than traditional mills – all while running on electricity generated by burning biomass from its own waste stream.

“We think there’s nothing in Canada that’s as sustainable as this project, in terms of what we bring in upstream and downstream benefits,” says William Walls, vice president of strategy and development, in a phone interview. He claims that the carbon footprint of Red Leaf’s wheat straw pulp is a third that of regular wood pulp.

Red Leaf has earned the confidence of investors, raising $42 million in five years, most of it from the container company Dart, as well as about $8 million in government funding and a $1-million angel investment. Walls calls it “probably one of the best-funded cleantechs in Canada.” The company used the funding to build a demonstration plant in Alberta, where it has been testing its process and selling its products for different applications. Once operational in 2028, the facility is expected to convert 400,000 tonnes of straw into 200,000 tonnes of market pulp annually.

There’s a lot for investors to like. For example, Red Leaf doesn’t need to develop any equipment to run its patented process for “making the straw act like a wood chip,” Walls says. They use conventional equipment for wood pulp mills made by Valmet, one of the biggest pulp and paper equipment manufacturers on the planet.

Red Leaf sources directly from farmers and accepts all varieties of leftover wheat straw, as well as oats, barley and flax, much of which would often otherwise be burned or left to lie on the field. This creates a new revenue stream for farmers and positions them in a circular economy, while ensuring a reliable supply of pulp for Red Leaf’s new mill.

An opening in the pulp market

The introduction of wheat straw pulp comes amid an ongoing decline in the supply of “economically viable timber,” which has been devastating for Canada’s forestry industry and prompted one B.C. lumber mill to close in November. The main culprits are wildfires, which consumed 17 million hectares in 2022, and invasive insect infestations, which killed 13 million hectares worth of trees the same year. Those disruptions, plus a reduction in the allowable cuts, caused the whole forestry sector to contract by 22% in 2023 and have shrunk the available wood fibre for products like pulp and pellets by more than 40% in British Columbia since 2018. To make matters worse, the United States raised its duties on softwood lumber to 20.6% last July.

The constrained fibre supply in Canada’s forestry sector creates an opening for Red Leaf, but the company sees its role as complementary rather than competitive, spokesperson Elle Kreitz says in an email: “Red Leaf introduces new, non-wood fibre into an already integrated system, helping to relieve supply demand pressures without competing for forest resources.”

The company believes its wheat pulp should telegraph its authentic sustainability, so they’re not going to dye it bright white, which has long been an industry norm. Red Leaf advertises its pulp as possessing a “natural golden tone” – one that doesn’t require a harmful bleaching process to achieve.

A starring role for lignin

Red Leaf also plans to sell the lignin – a component of plant cell walls that gives them their structure – separately as a stand-alone product. Straw has less lignin, so it’s easier to separate out, Walls says. Lignin comes out of the pulp process as a sludgy brown by-product that’s already a popular binder in animal feed and is considered eco-friendly because it diverts waste that would otherwise contaminate waterways.

But Walls sees much more potential for the sticky residue. Non-toxic but also not directly digestible, there is evidence that lignin has some health benefits as a food additive, and it can also be used in other industries as a natural bonding agent for materials manufacturing and pharmaceuticals. There are also emerging applications in batteries and bioplastics.

“It’s like a unicorn. We’re selling it for more than twice as much money as the pulp,” Walls says. “But someday down the road it may be that this thing is called Red Leaf Lignin and the pulp is the by-product.”

Mark Mann is the managing editor of Corporate Knights.