In 2020, the extraction, transport and manufacturing of materials for the building sector accounted for 10% of global greenhouse gas emissions. If buildings are to make meaningful contributions to keeping global temperature rise to 1.5 C above pre-industrial levels, limiting emissions from building materials is crucial.

To achieve this objective, engineered versions of age-old building technologies, like wood, straw or bamboo, are critical. These bio-based building materials generally demand less energy in manufacturing and have the ability to capture and store carbon through photosynthesis.

This is why experts in green building policy, climate science and architecture increasingly tout the benefits of transforming buildings from a giant source of carbon into a large carbon sink.

As scholars of business sustainability and bio-products markets, we closely observe the trends in green building and construction industries, and the reactions these provoke in sectors of the economy looking to cut emissions. With corporate announcements on the rise that publicize natural materials like wood as “the new concrete” in company offices and warehouses, we believe it’s time to take a closer look at the opportunities and limitations of making building materials part of a company’s net-zero carbon pledges.

The rise of net-zero carbon offices

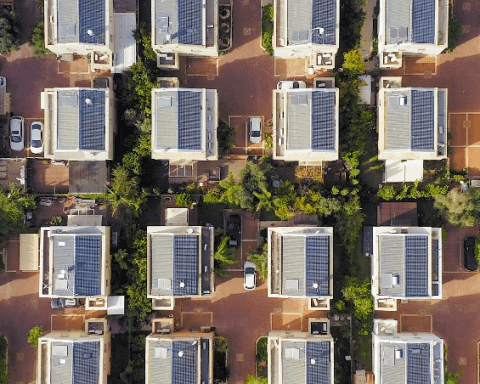

The past two decades have seen the use of green buildings as an explicit tool to reduce the carbon footprint of companies. It is now commonplace for business offices to feature the latest in engineering and building operations, from energy efficiency and on-site heating and cooling, to waste reduction and recycling.

Bloomberg’s European headquarters, for instance, has earned the title of the world’s most sustainable office building for combining all these measures. From a company perspective, going beyond operational efficiency, to also focus on building materials, is a logical step.

Walmart offers one prominent example of the use of bio-based building materials. The retail giant is set to finish its new home office in Bentonville, Ark., by 2025. It is the largest corporate campus project in the U.S. that uses mass timber, a group of large engineered structural wooden panels that have gained market acceptance following changes in building codes, for the construction of multi-storey and tall wood buildings.

Structurlam, a Canadian company that delivers mass timber, opened a fully automated facility in Walmart’s home state where it procures lumber from forests in the region to complete the project. Similarly, Google will soon finish its first mass timber office complex.

Microsoft already opened a building on its Silicon Valley campus that uses over 2,100 tonnes of cross-laminated timber (CLT), a wood panel system that is projected to reach a global market size of more than $3 billion within the next five years.

Some European firms like the German retail chain Alnatura are using prefabricated loam in their headquarters, and automaker BMW is about to open an electric vehicle showroom in California that has flooring made from hemp wood.

Green construction meets prefab

What unites these technologies is a potential to combine climate benefits with the shift towards off-site construction and prefabrication, where the planning, design, manufacturing and partial assembly of building elements occurs at a location other than the final building site.

Many of the manufacturers that offer buildings made from bio-based materials are, in fact, a new class of technology start-ups that are backed by large investors.

Prefabrication helps optimize material use and model adaptive structures that can be deconstructed, modified and reassembled, thereby reducing the need for virgin resources.

This provides companies with immense flexibility in planning for the long-term use of their office buildings, sales stores, warehouses and factories, without having to think about demolishing a structure.

Limitations of bio-based building material

Bio-based building materials have their limitations. Harnessing their environmental potential requires that they are sourced from sustainable supply chains. From a climate perspective, building wooden office towers with timber can be counterproductive if large amounts of carbon dioxide are emitted in the logging, transport and manufacture of wood products.

A company may also ask whether new buildings are needed in the first place. After all, the lowest carbon footprint is that of a building that is never constructed.

Companies may consider using bio-based building materials in retrofitting and remodelling existing offices or factories instead of building new ones. Serial retrofit initiatives, of the kind spearheaded by governments in Europe and suggested for Canada, already funnel capital into the scale-up of industries for prefabricated building technologies, like facades made from wood and recycled materials.

Ultimately, as with all corporate environmental strategies, simply introducing bio-based products and materials to the company, be it in office buildings or elsewhere, without having resources in place to monitor their environmental efficacy (for example, in procurement, installation and use) can backfire.

The future of bio-based building materials

Building materials can play a key role, when considered as a part of a broader strategy in companies’ efforts to reach net-zero emissions. Over 450 firms around the world have already pledged to finance the transition to net-zero emissions by 2050.

The issue of materials in construction is gaining attention at the global scale as well. With more than 130 events focused on the built environment at the COP26 summit in November, buildings received more attention than ever.

That being said, bio-based products and materials will require even more attention going forward. A likely bottleneck in assessing when and how to use bio-based building materials, will be just how quickly industries normalize the use of life cycle costing tools, such as whole life carbon accounting.

Progress on the adoption of these tools has been slow, but the recent signing of whole life carbon requirements by 44 large companies offers hope that the time for net-zero carbon buildings may indeed be ripe.

post-doctoral research fellow at the department of mechanical and industrial engineering at Ryerson University.

Cody Searcy is a professor of mechanical and industrial engineering, as well as vice-provost and dean of graduate studies at Ryerson University.

This article is republished from The Conversation under a Creative Commons license. Read the original article.