Across the fields of North America, agricultural residue from the fall harvest accumulates, bound for landfills, animal bedding or simply left to decompose into the soil. Or, the approximately 1.1 billion tonnes of biomass that is generated annually from the United States’ farms, forests and landfills – which is currently of little or no market value – could be repurposed into durable, weather-resistant building materials.

A handful of start-ups, many based in California, see all that plant matter as a potential feedstock for making products routinely used in housing construction – think insulation, flooring, panelling and concrete additives.

Not only would these bio-based products greatly reduce a building’s carbon footprint; in side-by-side comparisons, building materials made from straw, hemp, flax and cellulose are more fire-resistant than their conventional counterparts – a top-of-mind concern in the Golden State following the January wildfires that razed more than 50,000 acres of land, destroyed more than 16,000 structures and killed at least 29 people.

British Columbia and other parts of Canada have likewise experienced extreme weather events, from flooding to wildfires. “There’s going to be a really big push to create more houses in the near future,” says B.C.-based Elli Terwiel, owner and lead engineer at Sage Structural Engineering.

Terwiel is part of a growing movement of engineers, designers and architects that are trying to convince the construction industry that natural materials such as grain straw, corn stover (the stalks, leaves and cobs left over after the corn harvest), husks and even sewage sludge can be turned into high-performance building products. “The question is, how do we build those buildings better?” she asks. “How do we make these buildings the best that they can be for Canadians? And I do think that bio-based materials, whether just as insulation or the entire structure, there’s a place for them in the conversation.”

A recent report put out by RMI notes that many bio-based products are market-ready and are at or near cost parity today, despite most of these products not yet having reached the economies of scale of the incumbent building materials.

Mainstreaming natural building systems could, essentially, decouple economic growth from greenhouse gas emissions by transforming the high-emitting building sector into a carbon sink.

How did we get here?

The buildings and construction sector is by far the largest contributor to climate change, accounting for at least 37% of global emissions. In the United States alone, new home construction emits nearly 30 million tonnes of GHG emissions each year.

Until recently, architects and engineers have focused on reducing carbon emissions generated by the maintenance and operations of a building – the GHGs created from heating, cooling and lighting, which are projected to decrease from 75% of the sector’s total emissions to 50% over the next few decades.

But this assessment of a structure’s carbon impact doesn’t account for so-called embodied carbon. Embodied carbon refers to the GHGs released during the entire life cycle of a building, starting with the extraction of the raw materials used for construction through manufacturing, transportation, installation, use and disposal. The built environment relies on concrete, steel and aluminum, which are especially difficult to decarbonize and are responsible for a considerable proportion of a building’s embodied carbon load.

Studies have shown that as much as 60% of an average building’s carbon emissions are embodied as opposed to operational.

Everything old is new again

Bio-based building products are a highly effective way to reduce embodied carbon. Roughly 50% of the weight of plants is photosynthetically sequestered carbon. Buildings that pack mostly plant matter into their structures store substantially more carbon than the amount required to process and transport the materials themselves.

Straw, which is plentiful and a natural by-product of wheat, rice, rye and oats, sequesters 60 times more carbon than it requires to grow, making it one of the most powerful carbon-storing building materials in the world. “You’re taking what would be an agricultural waste product,” Terwiel observes, “that might break down in the field, and you’re putting it into a building. You’re storing carbon in buildings.”

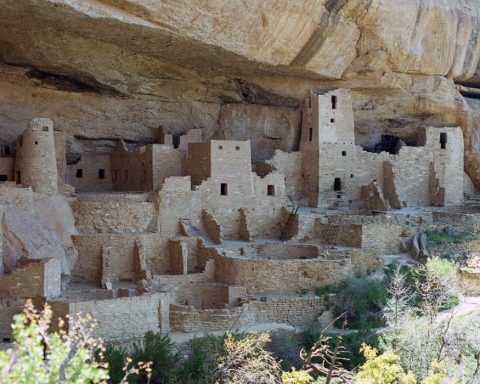

Using natural building materials is not an entirely new idea. Cob, a mixture of clay and straw, is a traditional building technique in the United Kingdom, where cob houses dating back several hundred years still stand. Traditional straw bale construction has been employed for more than a century in the United States. Using cellulose (finely shredded cardboard fibres and recycled paper) for building insulation dates back many centuries in both the United States and Canada.

Code work

David Arkin, a principal at Arkin Tilt Architects, a firm that specializes in ecological planning and design based in Berkeley, California, has built dozens of straw bale structures as well as a four-unit townhome project in Oregon that achieved an 85% reduction in embodied carbon through the use of natural building materials.

The challenge of such structures – and there are several – is that straw bales, like so many biomass products, must be purchased directly from the source, in this case the local farmer. “It’s a matter of scale,” Terwiel says. “You have these very small producers who are at the early adopter stage, who haven’t achieved scale to be able to go after Rona or Home Depot. You have to know where to look to find these products and the people who know how to work with them.”

Moreover, walls insulated with plant matter tend to be much thicker than typical ones. While this has its benefits – excellent thermal properties, soundproof rooms – it can also be impractical in high-density, urban settings. Which is why Anthony Dente’s firm, Verdant Structural Engineers, also based in Berkeley, has been developing a drop-in structural wall panel made from straw bales that fits conventional dimensions, complies with California’s building code and eliminates the need to visit the local farmer. Verdant plans on launching the panels in early 2026.

“I’ve given a lot of presentations to architectural firms,” Dente says. “I don’t talk about how they can buy 100 straw bales from the farmer and have a bunch of their friends stack them up in their walls. I’m talking to them about product development and efficiency and material science development and that they can start bringing these materials to their more conventional clients.”

The majority of plant-derived products, however, have yet to appear in building codes. Projects tend to be small-scale one-offs as a result, and mostly residential.

The compostable house

“Building for disassembly” refers to buildings that are designed so that every component can be removed and reused rather than tossed into a landfill where carbon is released into the atmosphere. For instance, hempcrete, derived from the hemp plant, is a superb insulating material and can also be used in place of concrete; it is lightweight, fire-resistant and entirely recyclable or reusable. “At the end of life, when you remove the finishes, you can take a building made with natural materials and it will compost itself. And that, I think, is pretty incredible,” Terwiel says.

The RMI report cites a project that compared two residential homes, one built using standard, off-the-shelf materials, the other incorporating bio-based products in the flooring, panelling, rooftops and insulation. Equal in size, the carbon-storing model showed a 107% reduction in net emissions, tipping the building into net storage territory.

“By 2030? I’d like it if California has adopted and green-lighted the use of clay construction,” Dente says. “Clay construction is incredibly fire-resistant and high-performing – we make ovens out of clay! It’s kind of silly how hard it is to use a system that’s such a no-brainer fire solution.”

Victoria Foote is a writer and editor who specializes in clean energy and climate.